Pattern digitizing is a vital phase of manufacture in several industries where the primary focus is the production of sewn products and metal sheets. In the apparel and garment industry, pattern digitizing is the process that entails sewing patterns for multiple purposes such as halter dresses scanning, maxi dresses digitizing, or wrap dress digitizing. There are two ways to digitize patterns and we shall be discussing those in detail in the entirety of this article. Typically, the initial patterns are made of cardboard, plastic, or paper, and then they are either scanned into the Computer-Aided Design (CAD) system or one can simply employ a CAD table to create a digital representation of the design itself.

1. Hand Digitizing Method

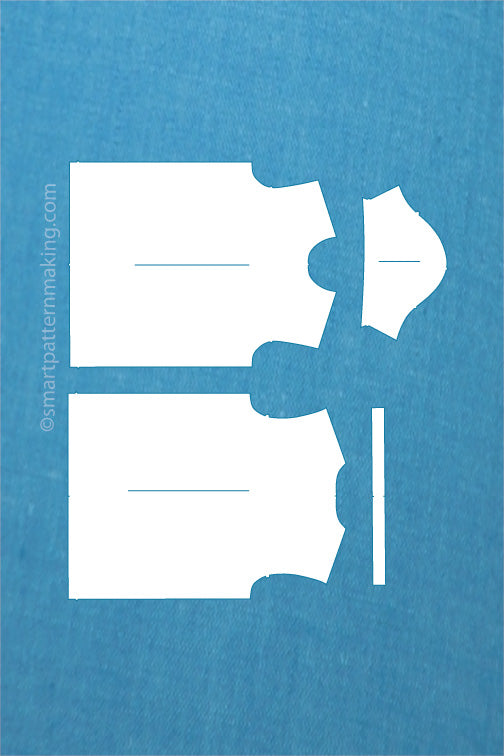

This method entails employing a digitizing table. Digitizing tables are, basically, electromagnetic tables that incorporate a special type of cursor. This cursor enables the user to traverse the outline of patterns point by point. The digitizer's cursor or pen creates a magnetic field that is sensed by the electrical grid in the table. While creating the pattern, press the tip of the pen or just push a button on the cursor. This will send a coordinate to the computer, that is linked via USB, representing the specific position on the table. The CAD/CAM program is linked to this table and the pattern is fed into this program following the movement of the mouse. You can fix the patterns on the table surface by employing adhesive tapes and then removing them.It is important to note that before beginning with this method, you need to ensure that the digitizer is calibrated.

Pros

• This method allows an elevated level of freedom to the artist.Cons

• The process is very slow due to the fact that everything is done manually.• It consumes a lot of the user’s time.

• Table digitizers have many components that are hard to use and find.

• The tables are inconvenient due to their large size.

• The level of accuracy is considerably lowered.

2. Scanning Method

This method entails the use of scanners to digitize pattern designs such asHalter dresses scanning, maxi dresses digitizing, or wrap dress digitizing.

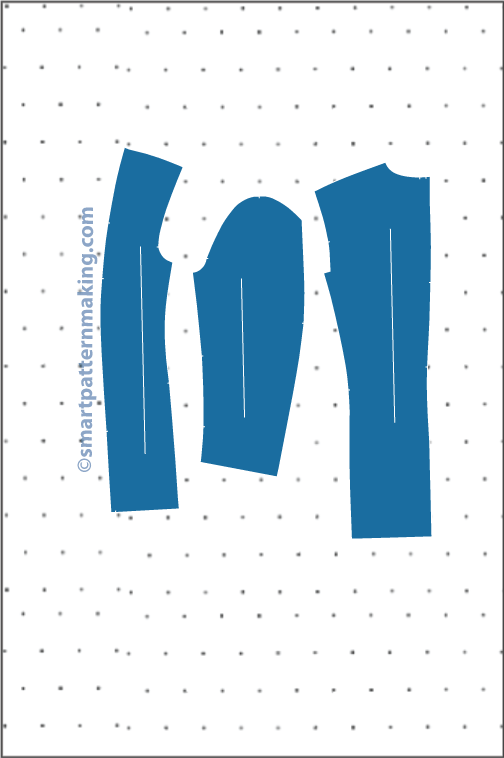

The paper must be flat to ensure accurate piece digitizing. Moreover, while you send out your patterns to be digitized, make sure that all your pattern tracings are clearly visible and marked with dark, hard lines.

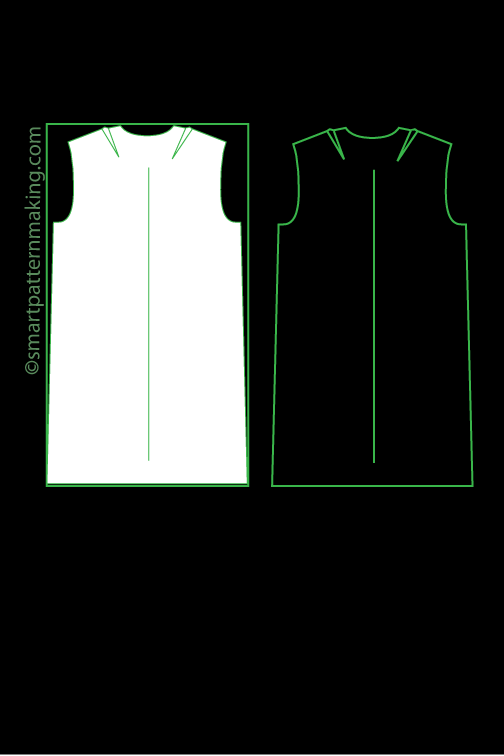

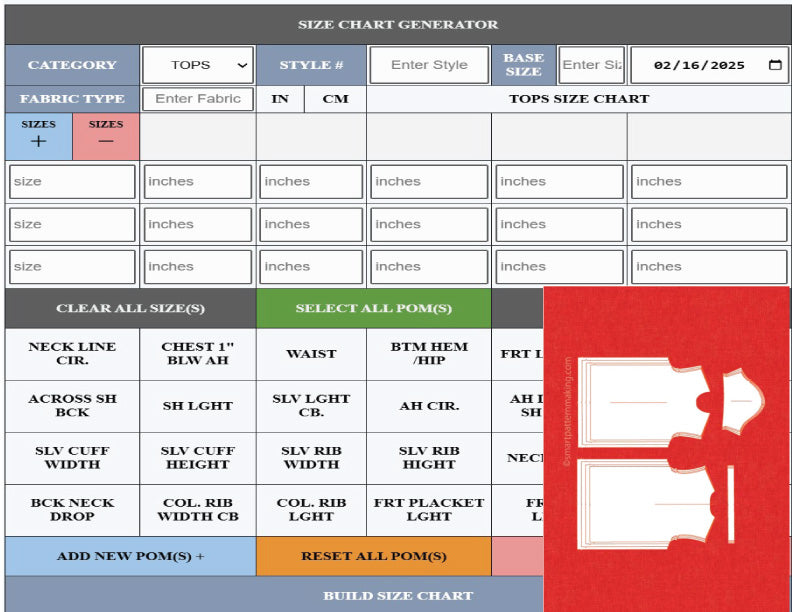

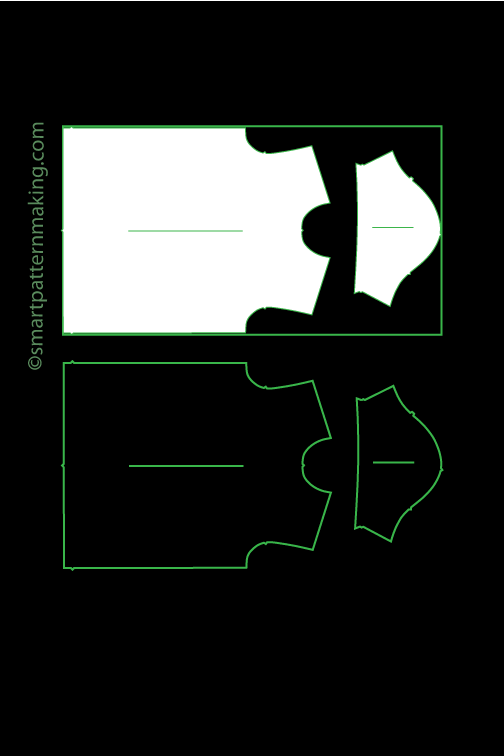

Scan the Finalized Design

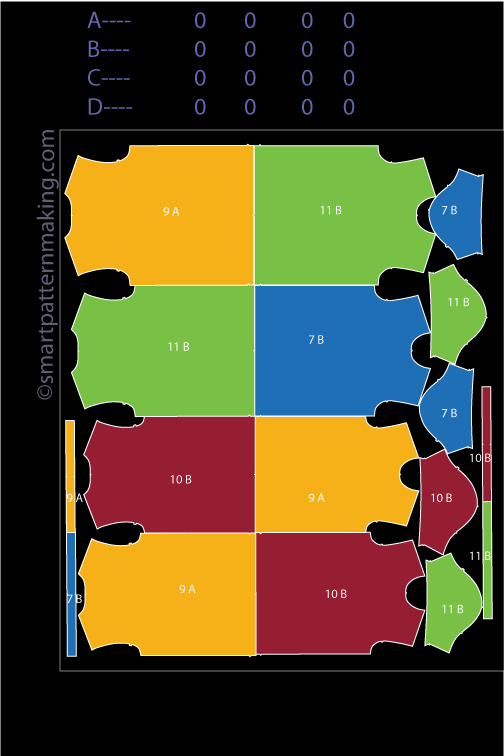

This is where you digitize your pattern so that it can be easily preserved and maintained. A pattern card ought to be provided accompanying the fabric description and detailing for each piece.Reassemble the Individual Pieces

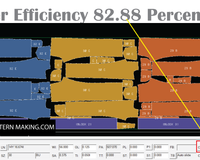

This is in case you are working with a substantially large design that you have scanned in bits. Otherwise, you can go right ahead to the next phase of this process.After having scanned all the separate pieces, it is time to make them into one pattern. Open the individual digital files in a digitizing CAD sofware and then piece them together on a wider canvas.

Pros

• Alterations and modifications can be done a lot faster and in an efficient way.• Your patterns will exhibit professionalism.

• There will be a higher level of accuracy.

• Time consumption is lowered.

• Cost is considerably lowered as well.

Cons

• It can prove to be a long process because it incorporates multiple steps.• it will accurately scan the perimeter of your pattern piece but some extra labor might be needed when cut outs or drill marks are present on patterns

Conclusion

From the aforestated facts, it is evident that the scanning method provides a lot of assistance and ease in terms of pattern digitizing; be it dresses pattern scanning, maxi dresses digitizing, or wrap dress digitizing. People are turning more and more towards having their apparel customized through an efficient and foolproof system i.e. scanner-employed pattern digitization.

Ready to start digitizing or scanning your patterns? Click the get started button below. we are apparel industry pattern digitizing company with 25 plus year experience in pattern digitization and scanning services.

Alejandro Esparza: Founder @ smartpatternmaking.com /Professional Pattern Maker/ Technical Designer/ Startup Advisor and acknowledged in the garment industry as authority in pattern making and pattern design process. He has the ability to work with small entrepreneurial companies’ private label customers and large organizations. Alejandro is a graduate of Los Angeles Trade Technical College Fashion Design Program. He has over 25 years of apparel garment industry experience and is part of Expert Ezine Articles Authors community since December 25, 2008 and has published multiple articles about the garment industry. Copyright © by Alejandro Esparza. All Rights Reserved. No part of this article may be copy or used without written Permission from Alejandro Esparza the Author.

------