Welcome to the world of fabric spirality. Spiral what? What in Neptune is Spirality? Spirality is a common problem in weft knitted fabric. It is the de- twisting tendency of yarn in the fabric. Now that we have clarify that let's learn about why and how spirality happens.

Why does spirality occur on fabrics and garments?

There are several causes as to why spirality or torque occurs on fabric and garments including Fabric Structure, count of yarns Fabric finishing, Fabric relaxation, Machine rotation, (GSM also known as gm/2) = grams per square meter which is the metric measurement of the weight of a fabric.

Studies done on fabrics demonstrate that the finer the yarns are on a fabric the more spiratlity or torquing will have due to more twisting.

Is there any machine or equipment that can test spirality of fabrics?

Yes, There is a machine called Spirality Tester. This machine is used to check dimentional distortion in circular knitted fabrics.

How to reduce fabric spirality?

Some Solutions that can alleviate spirality or torque on fabrics include: Resin treatment and Heat Setting. Steam or hot water reduces twist liveliness and hence spirality.

What seam twisting / shape distortion or spirality percentage would become a problem if present in bottoms/ pants?

Any spirality greater than 4 Percent would affect the look of a garment and take value away from it according to experience retailers and renowned buyers around the world.

What associations provides spirality test methods for textile products?

The below associations are the most common organizations that create standardization for textiles products.

These organizations have conducted hundreds of tests on textiles products and provide a dozen of test methods to calculate different behaviors of fabrics under different wash processes and also conduct Skewness / Spirality tests on fabrics.

What is the American Association of Textile Chemists and Colorists (AATCC)

The (AATCC) is a not-for-profit association that provides test method development, quality control materials, and professional networking for textile professionals throughout the world.

What is The International Organization for Standardization (ISO)

The (ISO) is an independent, non-governmental international organization that brings together experts from 165 nations to share and develop voluntary relevant international Standards that support innovation and solutions to global challenges.

What is (ASTM) International

The (ASTM) is an international standards organization that develops and publishes voluntary consensus technical standards for a wide range of materials, products, systems, and services.

Hope we have all learned the basics for fabric spirality (torquin) concept and what causes skewness change in fabric and garment Twist.

I will proceed now to talk about what is needed before we start calculating pants torquing percentage. To start the spirality test on a fabric or a garment the following conditions must preexist before testing garment twist (torquing).

The test specimens are to be conditioned in the standard atmosphere of 65% Relative Humidity (RH) +/- 2% and 20°C +/- 2°C for a minimum of 4 hours.

Calculating Pants Spirality

Let's Get Started:

Prepare bottoms/Pants to calculate spirality percentage. Test the pants in its finished state and record whether any spirality test method is present in the pants prior to washing.

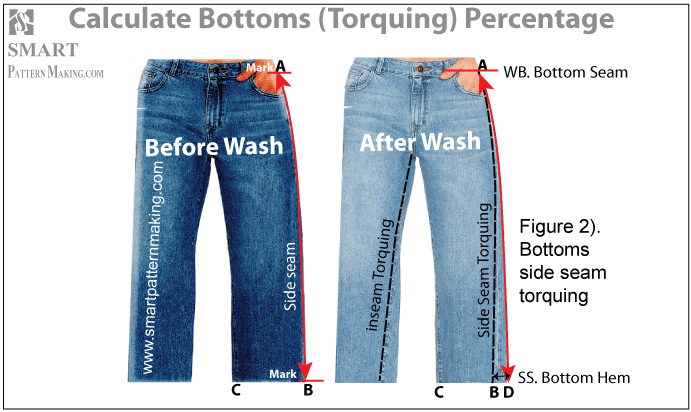

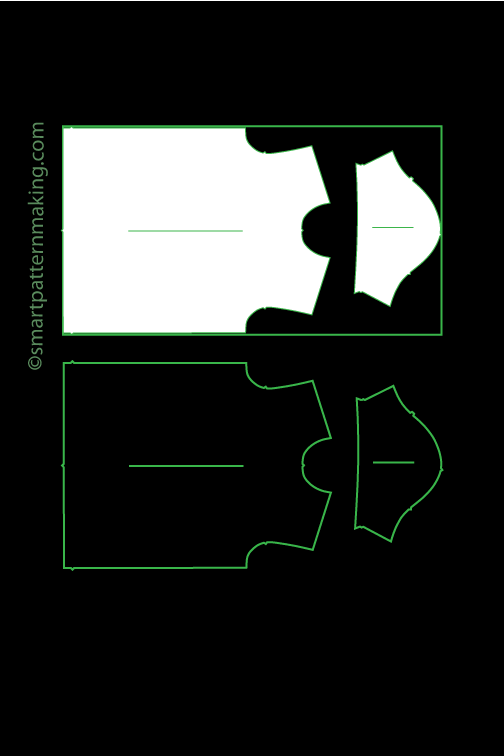

Then Measure original length and width dimensions. IMPORTANT: It is recommended that garments that already exhibit Spirality are not tested because deceptive results will be produced please see image below.

Before Wash:

Prepare pants and mark spirality marks at top and bottom of garment.

Step 1). Lay pants flat without tension on a table and Gently remove large wrinkles and creases. Begin smoothing from point (A) working down the Pant body.

Step 2). Using a fabric marker place 2 marks, one spirality mark at uppermost of the garment folded edge (point A) and the other spirality mark should be placed at the lower most point of the same folded edge or seam (Point B).

Step 3). wash and dry the Pants according to your recommended washing and dry process

After Wash:

Step 4). Prepare the pants after wash and lay pants flat without tension on a table and measure and record the distance from point A to point D.

Step 5).Measure and record displacement of perpendicular line at points B and D and apply the following formula below.

Suppose displacement of side seam at points B and D is 1" inch and the length of pants at side seam at points A and D is 42" using the formula below and substituting the points distance in between them by our imaginary numbers we have a total of 2.5 percent fabric spirality or (torquing).

Let's see the formula below and how we calculated this.

Pants Spirality Percentage Formula:

Spirality % =( BD/AD*100) or you could say Spirality% = (100* BD/AD)

Let's replace our alphabetical equation above with our imaginary numerical results or distance for points (B and D) and distance for points (A and D)

Spirality % =( 1/42*100)=2.38 =2.5 % OR Spirality% = (100* 1/ 42)= 2.38= 2.5%

----------------

Ready to start pattern making or resizing your own denim jeans designs or fashion brand jeans products? if so, Drop us a chat NOW and we’ll get you started!

Discover all of our Pattern Making, Digitizing, Resizing and Printing services all available to you and let our expert team grade up or down your next personal or business denim jeans styles today!

Loved reading this article and founded valuable? If so, Show us some love and buy us a coffee! ☕ :)

Developing tools and creating valuable content takes a lot of hours of work and days of research so that you can have them at your disposal. Also, keeping the content you read (Ads FREE) and operating this website cost a lot of money. So please, consider supporting us, so that we might continue to provide you with more valuable tools, fresh content, and to continue offering you with the best services that you deserve!

4 comments

Alejandro Esparza

Hi Everyone! What fabric torque issues have you had when washing or sewing your pants designs? COMMENT BELOW:

Alejandro Esparza

Hi Muhammad! -How much spirality percentage is considered ok in fabric? ANSWER: Spirality in fabric is generally considered acceptable if it falls within the range of 2-5%. However, it is important to note that the acceptable percentage may vary depending on the specific fabric type and its intended use. It is recommended to consult with fabric experts or manufacturers for specific guidelines on spirality percentage for different fabrics.

Muhammad Zain

How much spirality percentage is considered ok in fabric???

Mashuqur Rahma

Good