Introduction to pattern digitizing

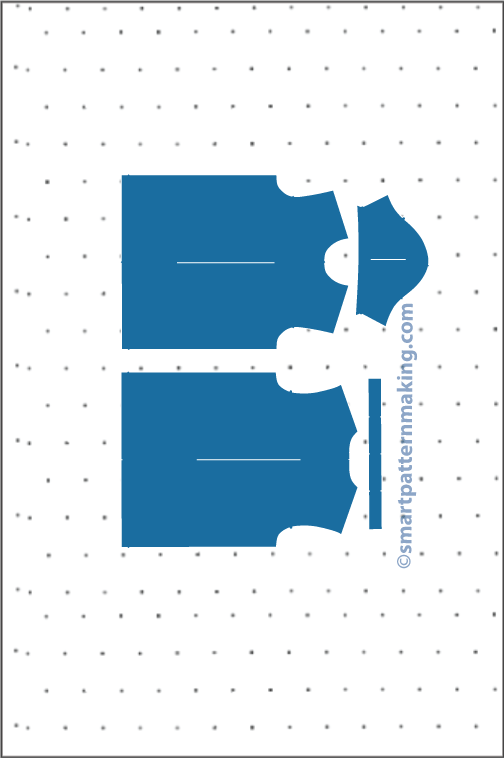

Pattern digitizing services involve the conversion of physical patterns, such as paper or fabric templates, into digital formats. By utilizing specialized digitizing services and equipment, designers can create accurate digital replicas of their patterns. These digital patterns can then be easily stored, manipulated, and shared, offering numerous benefits such as improved efficiency, increased accuracy, and enhanced collaboration among designers and manufacturers. The implementation of digitizing services has revolutionized the fashion industry, enabling faster production times, reduced material waste, and greater design flexibility. In this article, we will explore the concept of pattern digitizing services and discuss their advantages and implementation methods.

Why digitize patterns?

Digitizing patterns offers numerous benefits that make it a worthwhile investment. Firstly, having your patterns in a digital format allows for easy storage and organization of digitized patterns. Instead of dealing with stacks of paper patterns that can become damaged or lost, you can conveniently store your digitized patterns on your computer or in the cloud using digitization services.

Additionally, digitized patterns can be easily shared with others using a pattern digitization service. Whether you're collaborating with a team or selling your digitized patterns online, having them in a digital format makes it simple to distribute and send to others. This accessibility also allows for quick modifications and alterations to be made to the pattern digitizer, saving you time and effort.

What is a photo scanner?

A photo scanner is a device specifically designed to scan and digitize physical photographs, turning them into digital files that can be stored, edited, and shared electronically. Photo scanners use a combination of sensors and software to capture the image on a photograph and convert it into a digital format. This digitization process allows users to preserve and archive their old photographs, as well as edit and enhance them using photo editing software. Photo scanners are available in various types and models, ranging from standalone scanners to multifunctional devices that combine scanning, printing, and copying capabilities.

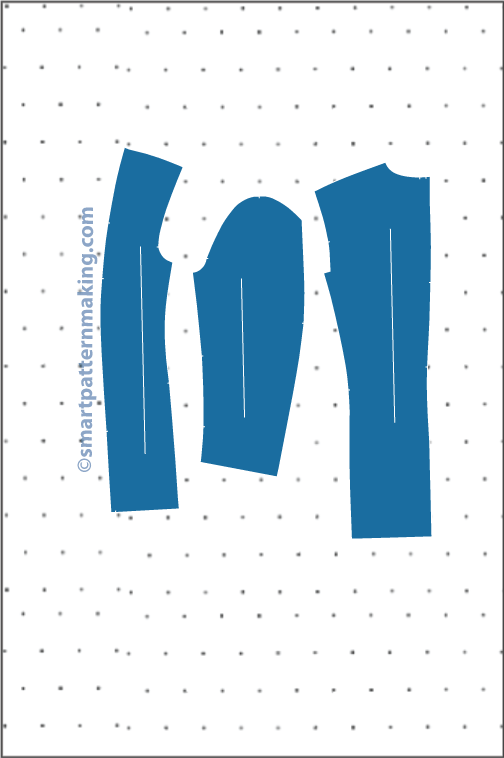

Types of photo scanners in the apparel industry

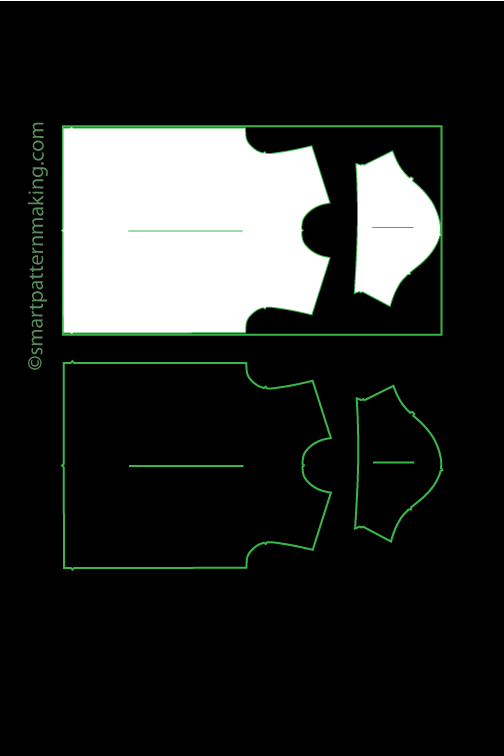

When it comes to digitizing patterns in the apparel industry, photo scanners play a crucial role. They enable designers and manufacturers to convert physical patterns into digital formats, making it easier to store, manage, and share them. There are 3 main types of photo scanners commonly used in the apparel industry: flatbed photo scanners, feeder photo scanners and 3D handheld photo scanners

Flatbed photo scanners are the most commonly used type of scanner in the apparel industry. They consist of a glass plate where the pattern is placed and a scanning head that moves across the plate to capture the image. Flatbed scanners are versatile and can handle a wide range of pattern sizes and materials. They provide high-resolution scanning, making them ideal for capturing intricate details and precise measurements. Flatbed scanners are often used in small to medium-sized businesses or for individual designers who require flexibility and accuracy in pattern digitization

Feeder photo scanners, also known as document scanners or automatic document feeders (ADFs), are designed for high-volume scanning. They are equipped with a document feeder that automatically feeds multiple patterns into the scanner, allowing for batch scanning. Feeder scanners are faster than flatbed scanners and are suitable for large-scale pattern digitization projects. They are commonly used in apparel manufacturing facilities or digitizing services that handle a large number of patterns on a regular basis.

3D Handheld photo scanners have become increasingly popular in the apparel industry for their role in virtual fitting experiences. These scanners allow designers to capture accurate 3D body measurements of customers, enabling them to create personalized patterns that guarantee a perfect fit . By digitizing the process of pattern creation and modification, handheld scanners streamline the design and manufacturing workflow, leading to improved efficiency and collaboration. This technology not only enhances the overall customer experience but also significantly reduces the need for physical fittings and alterations. With the use of handheld scanners, designers can ensure that every customer receives a garment that is tailored to their unique measurements and preferences . This level of customization and accuracy is only possible with the advanced capabilities of 3D handheld photo scanners

Furthermore, digitizing in the shoe industry, 3D handheld photo scanners are utilized to capture intricate details of shoe patterns, allowing for precise replication and customization. This ensures that every pair of shoes is made to the exact specifications of the design. Handheld photo scanners are an invaluable tool in the shoe industry, enabling designers to capture the intricate details of shoe patterns with remarkable accuracy. By scanning the patterns, designers can create digital replicas that can be modified and customized to meet the specific needs and preferences of customers. This technology not only enhances the efficiency and precision of the manufacturing process but also allows for greater collaboration between designers and manufacturers. With the use of handheld scanners, the shoe industry can deliver high-quality, customized footwear that meets the unique requirements of each customer.

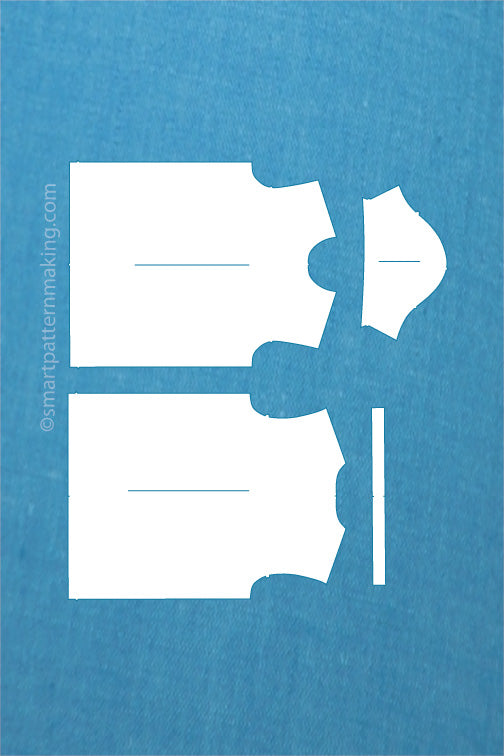

Digitizing Sewing Patterns with Expert Scanning Service

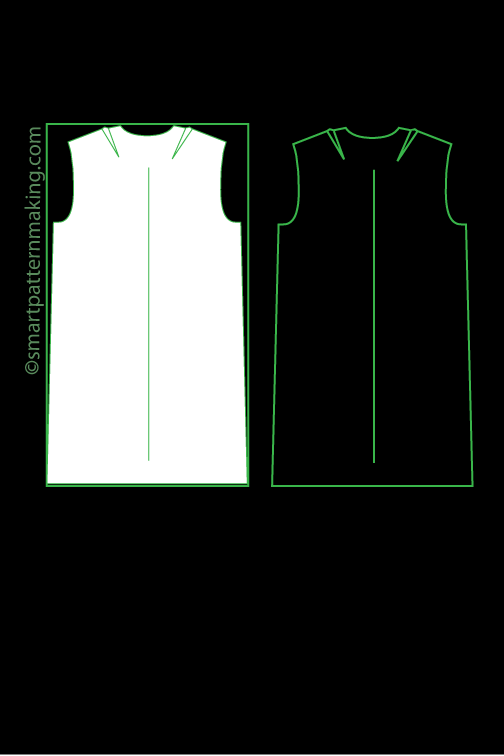

In the world of fashion, digitizing sewing patterns has become a crucial step in the design and manufacturing process. This process involves creating a digital version of a physical pattern by capturing its measurements, markings, and other details using specialized software or equipment. With the help of an expert scanning service, the digitization of sewing patterns becomes even more efficient and accurate.

An expert scanning service utilizes advanced technology to ensure precise and high-quality scanning of sewing patterns. By employing state-of-the-art scanning equipment, they can capture every intricate detail of the pattern, ensuring that nothing is lost in the digitization process. The scanning service professionals are trained to handle delicate and complex patterns, guaranteeing that the digital version accurately represents the original design.

With the digitization of sewing patterns, designers and manufacturers can enjoy various benefits. The electronic storage of patterns allows for easy access and sharing, eliminating the need for physical storage space and reducing the risk of damage or loss. Furthermore, digitized patterns can be customized effortlessly, enabling designers to modify and experiment with designs without the need for constant manual alterations. Overall, the expert scanning service plays a crucial role in simplifying pattern management and enhancing efficiency in the fashion industry.

The Pros and Cons of different pattern digitizing methods

The Flatbed scanner method

Pros of Flatbed scanners digitizing method:

- Accuracy: Flatbed scanners provide high-resolution scanning, resulting in accurate and detailed digital patterns.

- Ease of use: Scanning patterns with a flatbed scanner is a straightforward process and requires minimal technical skills.

- Time-saving: Scanning multiple patterns at once is possible with a flatbed scanner, saving time compared to other methods.

Cons of Flatbed scanners digitizing method:

- Size limitations: Flatbed scanners have limited scanning areas, so larger patterns may need to be scanned in sections and stitched together.

- Cost: Flatbed scanners can be expensive, especially high-quality ones with advanced features.

The Feeder scanner method

Pros of Feeder Scanners digitizing method:

- Efficiency: Feeder scanners can quickly process multiple documents, making it a time-saving option for digitizing patterns.

- Automation: Feeder scanners can automatically feed and scan patterns, reducing manual effort and increasing productivity.

- High volume capabilities: Feeder scanners can handle large volumes of patterns, making it suitable for businesses with high pattern digitizing needs.

Cons of Feeder Scanners digitizing method:

- Limited size options: Feeder scanners may have limitations in terms of the size of patterns they can handle, restricting the digitization of larger patterns.

- Potential damage: Feeder scanners may cause damage to delicate or fragile patterns if not handled carefully.

- Lack of versatility: Feeder scanners may not be suitable for patterns that require specialized scanning techniques or unconventional materials.

The Digitizing table method

Pros of digitizing table method:

- Versatility: It can handle a wide range of pattern sizes and types, making it suitable for various projects.

- Traceability: The digitizing table creates a traceable digital file, making it easier to identify and correct any errors or modifications in the pattern.

Cons of digitizing table method:

- Learning curve: Mastering the digitizing table method requires training and practice, which may take some time to become proficient in.

- Space requirements: Digitizing tables require a dedicated workspace with sufficient room to accommodate the table's size and accessories.

- Limited portability: Unlike other digitizing methods like tablets or cameras, digitizing tables are not easily portable and are mainly suitable for stationary use.

The Camera digitizing method

Pros of Camera digitizing method:

- Versatility: Camera digitizing can be used for various types of patterns, including large or irregularly shaped ones.

- Speed: Camera digitizing is generally faster than manual methods, allowing for quicker pattern conversion.

- High resolution: Modern cameras can capture detailed images, ensuring accurate digitization.

Cons of Camera digitizing method:

- Lighting conditions: Achieving consistent lighting can be challenging, potentially affecting the quality of digitized patterns.

- Dependence on camera quality: The quality of the camera used can impact the overall digitization results.

The Roll-Up digitizing method

Pros of Roll-Up Digitizing Method:

- Cost-Effective: Roll-up digitizing is a cost-effective method as it does not require expensive equipment or specialized software. It can be done using a regular home printer and basic image editing software.

- Accessibility: Roll-up digitizing allows for easy access to sewing patterns. Once digitized, patterns can be stored electronically and shared with others, eliminating the need for physical storage and transportation.

Cons of Roll-Up Digitizing Method:

- Limited Size: Roll-up digitizing is suitable for smaller patterns or individual pattern pieces. It may not be practical for large-scale patterns or patterns that require complex alterations, as they may not fit within the constraints of a standard home printer.

- Quality Limitations: The quality of the digitized pattern may be affected by the resolution and capabilities of the home printer and image editing software used. This can result in slight distortions or inaccuracies in the final digitized pattern.

- Time-Consuming: Roll-up digitizing can be a time-consuming process, especially when dealing with intricate patterns or patterns with multiple pieces. It requires careful alignment, scanning, and editing, which can be a tedious task.

CamScanner Mobile Phone Digitizing Method

Pros of Camscanner Mobile Phone Digitizing Method:

- Convenience: Mobile phone pattern digitizing and scanning allows for easy access and portability. Users can quickly scan and digitize patterns on the go, eliminating the need for bulky scanning equipment.

- Cost-effective: Mobile phone pattern digitizing and scanning can be a more affordable option compared to purchasing specialized scanning equipment. It eliminates the need for additional hardware and software, reducing overall costs.

- Time-saving: With mobile phone pattern digitizing and scanning, users can quickly capture and digitize patterns, saving time in the process. It eliminates the need for manual tracing or transferring patterns from paper to digital format.'

Cons of CamScanner Mobile Phone Digitizing Method:

- Quality limitations: Mobile phone pattern digitizing and scanning may not provide the same level of quality and accuracy as specialized scanning equipment. The resolution and image clarity may be compromised, affecting the final output.

- Limited scanning size: Mobile phone scanning capabilities are limited by the size of the phone's camera and the scanning app. It may not be suitable for scanning larger patterns or documents, restricting its usability in certain situations.

- Dependence on mobile phone: Mobile phone pattern digitizing and scanning relies heavily on the functionality and reliability of the user's mobile phone. Technical issues, battery life, or storage limitations can hinder the scanning process.

Pattern Digitizing Service: A Game-Changer for Multiple Sectors

Pattern digitizing service is a valuable tool that is used across multiple sectors, including the fashion industry, manufacturing, interior design, medical industry, automotive industry and even the aerospace industry. In the fashion industry, pattern digitizing services are used to convert physical patterns into digital formats, making them easier to store, manage, and share with others.

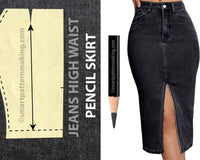

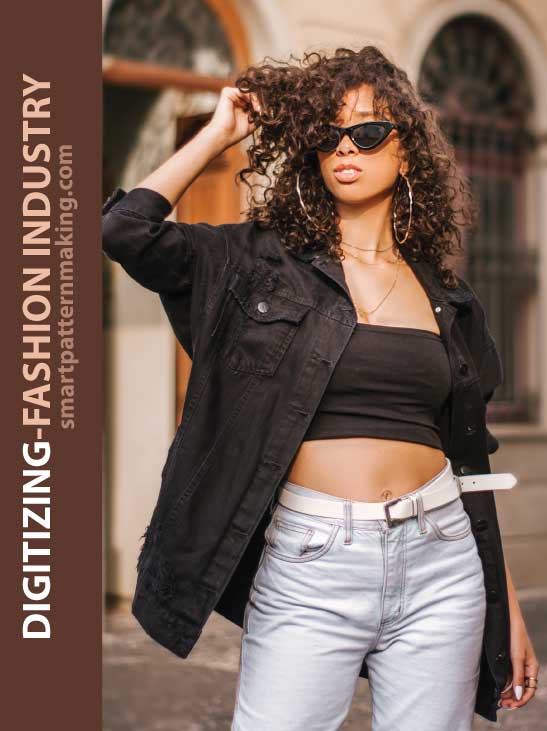

Digitizing fashion industry

Pattern digitizing service is an exceptionally advantageous digitizing service for designers, manufacturers, and other fashion industry professionals. This digitizing service enables them to effortlessly scan patterns and create precise and accurate digital patterns, which can be easily modified and adjusted as needed. By utilizing pattern scanning technology, designers can eliminate the tedious and time-consuming process of manual cutting and tracing. This saves them valuable time and effort, allowing for more efficient operations. Manufacturers, in particular, garner notable advantages from pattern digitizing services. By implementing pattern scanning techniques, they are able to produce patterns on a larger scale and with greater efficiency. The digital patterns generated can be easily shared and replicated using a pattern scanner, greatly reducing the chances of errors and ensuring consistency in production.

Digitizing interior design sector

In the interior design sector, the digitizing service for patterns is instrumental in creating digital templates for upholstery, curtains, sofas, covers, recliners, pillows, and tables, among other textile products. This, in turn, facilitates designers in visualizing how patterns will appear in various spaces and making changes as necessary. The scanning patterns become crucial when it comes to storing and managing digitized patterns: a systematic approach is indispensable to ensure convenient access and prevent any loss. Thus, using digital pattern management software or employing cloud storage solutions becomes imperative for organized pattern scanning and storing of digitized patterns.

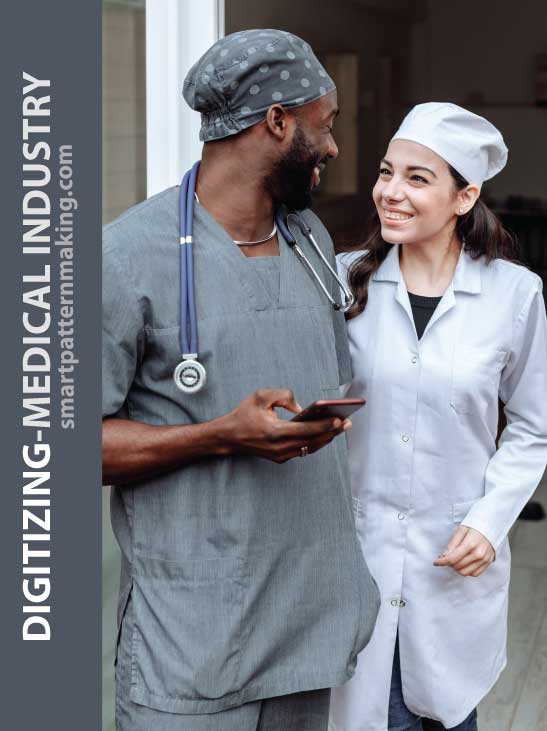

Digitizing medical industry

Pattern digitizing service in the medical industry ensures precision and accuracy in producing a wide range of medical garments and devices, including medical uniforms, bags, compression socks, lab coats, clogs, hospital gowns, patient gowns, disposable footwear, bibs, aprons, and gloves. They convert physical patterns into digital format using specialized equipment and software for pattern scanning, enabling easy storage, sharing, and modification of digitized patterns for improved efficiency and pattern scanning. This technology creates customized medical garments and devices tailored to individual patients for optimal fit and comfort. Digitizing patterns also promotes seamless collaboration between designers, manufacturers, and healthcare providers, facilitating the development of innovative medical products through pattern scanning and pattern scanning technology.

Digitizing automotive industry

In the automotive industry, pattern digitizing service plays an essential role in creating digital templates for various car components, including car interiors, seats, floor mats, seat covers, steering wheel covers, and more. By utilizing pattern digitizing, manufacturers can ensure a perfect fit and finish while streamlining the manufacturing process. This innovative technology of pattern scanning has revolutionized the automotive industry by allowing for greater precision and efficiency in the production of car interiors. With pattern scan in place, designers can easily create digital templates that can be utilized in the manufacturing process, resulting in high-quality car components. The use of pattern scanner ensures that digitized patterns are made available for seamless production.

Digitizing aerospace industry

Pattern digitizing services play a crucial role in the aerospace industry, particularly in the production of soft goods. Cloth-based materials are extensively utilized for creating seat covers, curtains, and upholstery for aircraft interiors. These materials are carefully selected for their exceptional durability, comfort, and fire resistance properties, ensuring the safety and comfort of passengers and crew members on board. Pattern digitizing allows for precise measurements and accurate scaling of these soft goods, ensuring a perfect fit and seamless integration within the aircraft's interior design. By utilizing digitizing services, aerospace companies can efficiently scan patterns, enabling the creation of digitized patterns. This pattern scanning process involves using a pattern scanner that accurately scans and converts patterns into digital form. The resulting digitized patterns can then be used for pattern integration.

The advantages of pattern digitizing services.

Pattern digitizing services offer several advantages that can greatly benefit businesses in the fashion and textile industry. Firstly, digitizing patterns allows for easy storage and organization of designs. Instead of dealing with stacks of paper patterns, digital files can be easily accessed and managed on a computer or cloud storage. This not only saves physical space but also reduces the risk of losing or damaging important patterns.

Secondly, digitized patterns can be easily scaled and resized without losing any details or accuracy. This is particularly useful when creating different sizes or variations of a design. With just a few clicks, patterns can be adjusted to fit specific measurements, saving time and effort in the production process.

Additionally, pattern digitizing services enable easy sharing and collaboration. Digital files can be easily shared with team members, manufacturers, or clients, allowing for seamless communication and feedback. This eliminates the need for physical pattern transfers or multiple copies, reducing the risk of errors or miscommunication.

Overall, pattern digitizing services offer numerous advantages that can streamline the production process and improve efficiency in the fashion and textile industry. By embracing digital technology, businesses can save time, resources, and ultimately deliver high-quality products to their customers.

What to Look for in a Pattern Digitizing Company: Expert Advice

When it comes to selecting a pattern digitizing company, there are several crucial factors to take into account. First and foremost, it is essential to ensure that the chosen digitizing company possesses the required expertise and experience in pattern digitizing.

Look for a team of skilled digitizers who have a deep understanding of the fashion industry and can consistently deliver accurate and high-quality results.

The technology and equipment employed by the digitizing company are also of utmost importance. Ensure that they utilize advanced software and equipment, such as digitizing tables, scanners, and pattern software, to guarantee precise and efficient scanning of patterns.

Turnaround time is another vital aspect to consider. Evaluate the company's ability to deliver digitized patterns within a reasonable time frame, particularly if you have strict deadlines to meet.

Security and confidentiality should never be overlooked. It is imperative to select a digitizing company that prioritizes the protection of your intellectual property. They should have robust data protection measures in place to ensure the safety and security of your patterns.

Customer reviews and testimonials can provide valuable insights into the quality and reliability of a digitizing company. Positive feedback from satisfied customers serves as an indicator of their expertise and professionalism.

While pricing is always a consideration, it is important to remember that quality and expertise are more important than cost alone. It is advisable to compare prices from different digitizing companies to ensure you are receiving a fair deal.

By taking these factors into consideration, you can make a well-informed decision when selecting a pattern digitizing company. A reputable and reliable digitizing company will assist you in unlocking the numerous benefits of pattern digitizing and enhancing your design process.

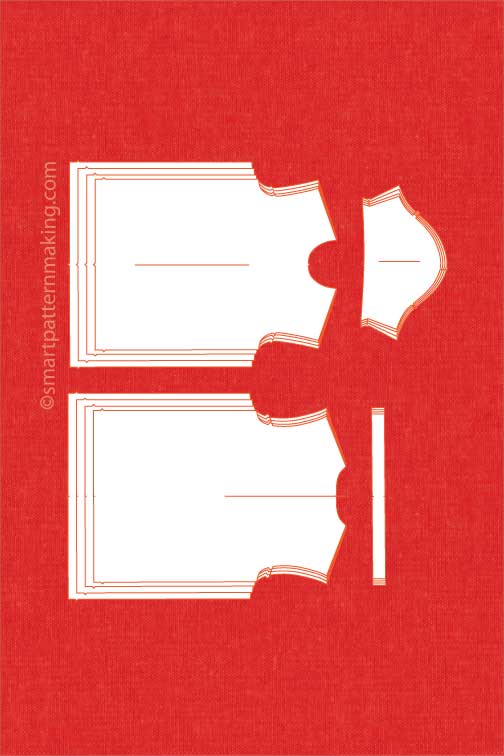

Tips for preparing paper patterns before digitization

Before you begin scanning your paper patterns for our digitization service, it's important to prepare them appropriately to ensure the best possible scan quality. Here are some tips for preparing your paper patterns for the digitize patterns process:

Inspect for damages: Carefully examine your paper patterns for any tears, creases, or other damages. If you encounter any, try to repair them as much as possible before scanning. A pattern scan with damages may result in inaccurate scans.

Flatten the patterns: If your paper patterns are curled or wrinkled, flatten them out as much as possible. Place heavy books or objects on top of them for a few hours to help straighten them before the pattern digitization begins.

Clean the patterns: Remove any dirt, dust, or debris from your paper patterns before scanning. Use a soft, lint-free cloth or brush to gently clean the surface for a clean pattern digitization.

Remove obstructions: Ensure that there are no obstructions on the patterns, such as sticky notes or pins. These can interfere with the pattern scanner during the scanning process and result in inaccurate scans of your pattern.

By following these simple steps, you can ensure that your paper patterns are in the best possible condition for pattern digitization, resulting in high-quality digitized patterns. Our digitized patterns will be a perfect replica of your original paper patterns.

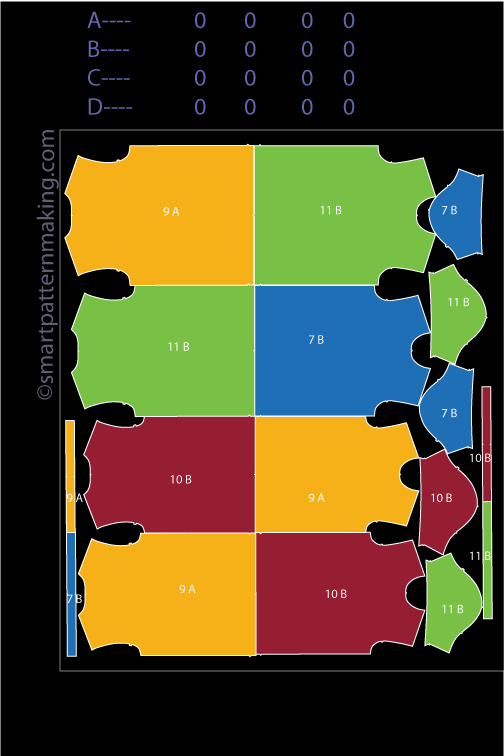

Maximize Scan Quality with Cutting-Edge Digitizing Services

Digitization services, also known as digitizing, play a crucial role in enhancing pattern scan quality by converting physical documents into a digital format. These services leverage advanced technology and techniques, using specialized software and cutting-edge equipment to capture intricate pattern scan details. State-of-the-art scanners and cameras ensure precise pattern capture, while digitization software enhances accuracy. Digitized patterns can be saved in various formats for easy sharing, editing, and printing. This versatility allows for efficient collaboration and workflow management.

Digitization services also offer streamlined storage, reducing physical storage needs and enabling easy backup and secure cloud-based storage. Users can digitize pattern scan documents without compromising the original. Overall, digitization services maximize pattern scan quality and enable efficient digital workflows.

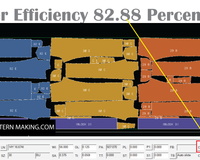

Digitized patterns offer a range of advantages beyond improved pattern scan quality. They can be easily shared in various file formats, making them compatible with different software and equipment. USA digitization services, in particular, also contribute to cost savings by eliminating physical pattern scan storage and reducing the risk of errors and rework. Additionally, designers can optimize fabric usage and minimize waste through efficient pattern scan nesting. Overall, digitization services provide a powerful tool for improving efficiency, productivity, and cost-effectiveness in pattern creation.

Why Use digitizing company's cutting edge digitizing software

Digitizing has become an essential part of the fashion and apparel industry, and utilizing a digitizing company's cutting-edge software offers numerous benefits. Gerber Accumark, Lectra Modaris, Tukatech, and PatternSmith are some of the leading digitizing software solutions available from a digitizing company.

These software solutions offer advanced features and tools specifically designed for pattern digitization. They allow for precise and accurate capturing of pattern measurements, contours, and details. This ensures that the digitized patterns are an exact representation of the original, reducing errors and improving overall quality.

Using cutting-edge digitizing software from a digitizing company also saves time and effort. Manual tracing and drafting are eliminated, allowing for faster pattern creation and modification. Additionally, digitized patterns can be easily stored, organized, and accessed, resulting in better pattern management.

Collaboration becomes seamless with digitized patterns from a digitizing company. Designers can easily share and work together on the same patterns, leading to improved efficiency and productivity. The ability to resize, adjust, and customize patterns digitally provides flexibility and versatility in the design process.

Overall, utilizing a digitizing company's cutting-edge software such as Gerber Accumark, Lectra Modaris, Tukatech, or PatternSmith offers convenience, accuracy, and efficiency in pattern digitization, leading to enhanced productivity and superior results in the fashion industry.

Common Challenges and Troubleshooting in Pattern Digitizing Services

Pattern digitizing services have become increasingly popular in the fashion and textile industry. They offer a convenient and efficient way to convert physical patterns into digital formats, saving time and effort for designers and manufacturers. However, like any other service, there are common challenges and troubleshooting that may arise during the process. Here are some of them:

- Pattern Condition: One challenge in pattern digitizing services is dealing with patterns that are not in optimal condition. Soft paper patterns, for example, may have curled edges or wrinkles, which can affect the accuracy of the digitized pattern. Digitizing services may charge an additional fee for line enhancement or pattern preparation to ensure the best possible outcome.

- Pattern Size: Another challenge is the size of the pattern. Most digitizing services have limitations on the maximum length or width they can digitize. If a pattern exceeds these dimensions, additional charges may apply for cutting and merging the pattern pieces.

- Workload and Turnaround Time: Digitizing services usually have multiple clients and projects in progress at any given time. This can lead to delays in digitizing patterns, especially during peak seasons. While some services offer quick turnaround times, it's essential to communicate with the service provider to determine an estimated timeline for your specific project.

- Pattern Complexity: Complex patterns with intricate details, multiple layers, or unconventional shapes can pose a challenge for digitizing services. Ensuring that the digital pattern accurately reflects the original design may require additional time and expertise.

- Communication and Collaboration: Clear communication between the client and the digitizing service is crucial for a successful outcome. Misunderstandings or lack of information can lead to errors in the digitized pattern. Providing detailed instructions, reference materials, and regular updates can help minimize potential issues.

- Quality Control: Digitizing services should have robust quality control measures in place to ensure the accuracy of the final product. This includes checking for any missing or distorted elements, ensuring proper alignment and scaling, and verifying the overall integrity of the digitized pattern.

- File Compatibility: Different software programs and systems may use various file formats for digitized patterns. Compatibility issues can arise if the files are not compatible with the client's software or machinery. Digitizing services should provide patterns in commonly used file formats or offer conversion options to address this challenge.

- Cost: The cost of pattern digitizing services can vary depending on factors such as pattern complexity, size, and the number of pieces to be digitized. It's essential to clarify the pricing structure and any additional charges upfront to avoid any surprises later on.

- Data Security: Given the sensitive nature of design files, data security is a significant concern in pattern digitizing services. Service providers should have robust security measures in place to protect client information and intellectual property.

- Customer Support: Adequate customer support is crucial for a smooth and satisfactory experience with digitizing services. Prompt responses to inquiries, clear communication channels, and assistance with any issues or concerns are essential aspects of good customer service.

Enhancing Efficiency with USA Digitizing Services for Pattern Creation

Digitizing services in the USA offer a convenient and efficient solution for digitization pattern creation. By converting analog or physical patterns into a digital format, these digitizing services streamline the pattern-making process and provide numerous benefits.

The process of digitizing sewing patterns involves using specialized digitization software and equipment. First, a scanner or digital camera is used to capture an image of the physical pattern and convert it into a digital file. Digitizing pattern digitizing software is then utilized to import the scanned image and convert it into a digital pattern that can be edited and manipulated.

With the help of digitizing services, the pattern creation process becomes faster and more accurate. Digitized patterns can be easily stored, modified, and shared electronically, eliminating the need for physical storage space and reducing the risk of damage or loss.

By outsourcing digitizing services, businesses can focus on their core competencies and save valuable time and resources. USA digitizing services often employ skilled professionals who have expertise in pattern creation and can ensure the highest level of accuracy and quality.

Furthermore, digitizing services offer flexibility and customization options. Digitized patterns can be easily resized, adjusted, and modified to meet specific requirements. This allows for greater design flexibility and the ability to cater to different sizes and styles.

In conclusion, USA digitizing services for pattern creation enhance efficiency by converting analog patterns into a digital format. These digitizing services offer convenience, accuracy, and customization options, allowing businesses to streamline their pattern-making process and achieve better results. By leveraging digitizing services, businesses can save time and resources while ensuring the highest level of accuracy and quality in their pattern creation endeavors.

How to Store and Manage Digitized Patterns: A Comprehensive Guide

Storing and managing digitized patterns is an essential part of the digitization process. Once you have created digital versions of your sewing patterns, it is important to organize and store them in a way that allows for easy access and retrieval.

One of the best ways to store digitized patterns is by using a dedicated folder or file management system on your computer. Create a separate folder for each pattern or pattern collection, and give them descriptive names for easy identification. Within each folder, you can further organize the files by categorizing them into subfolders based on garment type, size, or any other relevant criteria.

Another option is to use cloud storage services such as Dropbox, Google Drive, or iCloud for digitizing your patterns. These platforms allow you to store your digitized patterns online, making them accessible from any device with an internet connection. Cloud storage also provides the added benefit of automatic backup, ensuring that your patterns are safe and secure.

When it comes to managing digitized patterns, it is important to keep track of any modifications or updates made to the patterns. Consider maintaining a document or spreadsheet where you can record any changes, such as resizing, grading, or alterations, for digitizing. This will help you keep track of different versions of the pattern and ensure that you are always working with the most up-to-date version.

Lastly, it is crucial to have a backup strategy in place to protect your digitized patterns from loss or damage. Regularly backup your pattern files to an external hard drive, USB drive, or another secure location while digitizing. This will provide an additional layer of security and peace of mind.

By following these guidelines for storing and managing digitized patterns, you can ensure that your digital sewing library remains organized, easily accessible, and protected for years to come.

Conclusion and final thoughts on pattern digitizing

In conclusion, pattern digitizing plays a crucial role in various sectors, especially the fashion industry. The process of converting physical sewing patterns into a digital format offers numerous advantages such as increased accuracy, efficiency, and accessibility. Digitized patterns can be easily manipulated, graded, and customized, saving time and resources for fashion professionals. Additionally, digital pattern management allows for easy storage, sharing, and backup of patterns, ensuring their longevity and availability. With the ever-evolving landscape of fashion and technology, pattern digitizing is becoming an essential tool for designers, manufacturers, and other sectors that rely on pattern creation and management.

Pattern Digitizing Frequently Asked Questions FAQ(s)

What is Digitization?

Answer: Digitization refers to the process of converting analog information or physical objects into a digital format. It involves capturing and converting data or objects into a series of binary digits (0s and 1s) that can be stored, processed, and transmitted by computers or other digital devices. In the context of sewing patterns, digitization involves scanning physical patterns and transforming them into digital files, usually in a vector format, which can be easily manipulated and used for various purposes like storage, editing, sharing, and production. Digitization has become increasingly important in various industries, including fashion and apparel, due to its ability to streamline processes, improve efficiency, and enable innovation.

Digitization Definition

Answer: Digitization refers to the process of converting analog information into a digital format, typically represented by binary code (0s and 1s). This conversion allows the information to be stored, processed, and transmitted by computers and other digital devices. Digitization can be achieved through various methods such as scanning, optical character recognition, recording, and sampling. The popularity of digitization has increased with the advancement of computers and the internet, enabling the conversion of different types of information like text, images, audio, video, and data from barcodes and QR codes into digital formats.

How do you digitize in pattern making?

Answer: Digitizing in pattern making involves preparing your pattern by ensuring it is clean and flat. To digitize, you will need specific tools such as a digitizing tablet, pattern paper, and a computer with pattern making software. These tools allow you to convert your physical pattern into a digital format, making it easier to manipulate and modify on a computer.

What is Digitization?

Answer: Digitization refers to the process of converting analog information or physical objects into a digital format. It involves capturing and converting data or objects into a series of binary digits (0s and 1s) that can be stored, processed, and transmitted by computers or other digital devices. In the context of sewing patterns, digitization involves scanning physical patterns and transforming them into digital files, usually in a vector format, which can be easily manipulated and used for various purposes like storage, editing, sharing, and production. Digitization has become increasingly important in various industries, including fashion and apparel, due to its ability to streamline processes, improve efficiency, and enable innovation.

What is Digitizing a pattern?

Answer: Digitizing a pattern refers to the process of converting a physical pattern into a digital format. This is commonly done in the manufacturing and production industries, where physical patterns made of various materials are converted into digital vectors. Specialized software and equipment are used to capture the shape, size, and details of the pattern, creating a digital representation that can be easily stored, edited, and shared. Digitizing patterns is particularly important in industries such as fashion and textiles, as it allows for more precise and efficient production processes.

What is digitizing?

Answer: Digitizing refers to the process of converting analog information or physical objects into a digital format. In the context of sewing patterns, digitizing involves creating a digital version of a physical pattern by capturing its measurements, markings, and other details using specialized software or equipment. This allows the pattern to be stored, manipulated, and shared electronically, offering advantages such as ease of customization, accuracy, and accessibility. Digitizing sewing patterns is a common practice in the fashion industry, as it simplifies pattern management and enhances efficiency in the design and manufacturing process.

What is digitizer in garment industry?

Answer: In the apparel industry, a digitizer is a person or a machine that converts a design or pattern into a digital format. This digital file can then be used for various purposes, such as embroidery, printing, or manufacturing. A digitizer uses specialized software to create a digital representation of the design, which can be edited, resized, and manipulated as needed. This process is essential for creating accurate and high-quality garments.

What are the two methods of digitizing?

Answer: When it comes to digitizing, there are two main methods that can be used. The first method is manual digitizing, which involves tracing the features on a map or image to create digital vector data. The second method is scan digitizing, which is an automated process that uses scanning technology to convert physical maps or images into digital format.

Digitization meaning

Answer: Digitization refers to the process of converting analog information or physical objects into a digital format. In the context of sewing patterns, digitization involves creating a digital version of a physical pattern by capturing its measurements, markings, and other details using specialized software or equipment. This allows for easy storage, sharing, and backup of patterns, ensuring their longevity and availability. With the ever-evolving landscape of fashion and technology, pattern digitizing is becoming an essential tool for designers, manufacturers, and other sectors that rely on pattern creation and management. Digitization simplifies pattern management and enhances efficiency in the design and manufacturing process, making it a common practice in the fashion industry.

What is an example of a digitizer?

Answer: An example of a digitizer is a graphics tablet or pen tablet. These devices enable users to draw or write on a specialized surface using a stylus. The movements made on the tablet are then captured and converted into digital data, which can be utilized in various applications such as graphic design or digital art. Another example of a digitizer is a digital camera. When light enters through the camera lens, the camera's hardware and software convert that information into binary data, which is then stored as an image file.

What is a digitizing software?

Answer: A digitizing software is a computer program that converts analog information into digital format. It is commonly used in industries such as embroidery, where designs are created on a computer and then translated into stitches for embroidery machines to follow. Digitizing software allows for precise control and customization of designs, and it is an essential tool for creating high-quality digitized files.

Is scanning and digitizing the same thing?

Answer: Scanning and digitizing are similar processes, but they are not exactly the same. Scanning refers to the process of converting physical documents or images into digital files using a scanner. Digitizing, on the other hand, is a broader term that encompasses various methods of converting analog information into digital format, including scanning but also other techniques such as photography or audio/video recording.

Why is digitizing software so expensive?

Answer: Digitizing software can be expensive due to several factors. Firstly, the development and maintenance of high-quality software requires a significant investment in research and development. Additionally, digitizing software often requires advanced algorithms and complex coding, which adds to the cost. Furthermore, the demand for digitizing software is relatively niche, which means that the customer base is smaller, leading to higher prices to cover the development costs. Lastly, the value that digitizing software provides, such as increased efficiency and accuracy, can justify the higher price for businesses that heavily rely on digitization.

How do you digitize a sewing pattern?

Answer: Digitizing a sewing pattern involves scanning the paper pattern into a digital format using a scanner or a camera. Then, the digital image is imported into pattern-making software where it can be edited, resized, and printed. There are also professional services available that can digitize sewing patterns for you.

Can you digitize car seat cover patterns?

Answer: Yes, We Can. Please trace off all your car cover patterns on white soft paper and send us just a copy of each design that needs to be digitized. If you have pattern pieces that are bigger than 40" in length or width we will cut and stitch your pattern piece with our state of the art digitizing software and merge pattern pieces back to its original one piece pattern dimensions. Please fold your paper traced off car seat covers and place them inside a box when shipping your patterns to us.

Can you digitize furniture cover patterns?

Answer: Yes, We Can. Please trace off all your furniture cover patterns for sofas or recliners on white soft paper and send us just a copy of each design that needs to be digitized. If you have pattern pieces that are bigger than 40" in length or width we will cut and stitch your pattern piece with our state of the art digitizing software and merge pattern pieces back to its original one piece pattern dimensions. Please fold your paper traced off furniture cover patterns and place them inside a box when shipping your patterns to us.

How soon can you have my patterns digitized?

Answer: We can have all your patterns digitized as soon as next business day. However, keep in mind that we always have work in process meaning we also have other clients patterns that need to be digitized as well, so timing will be established according the the amount of work load we have and the day and time that we receive all your patterns.

Can I drop off my patterns at your location?

Answer: No, you can not. We are an online service company only. We track all patterns and packages received from our clients via Fedex. Any patterns to be digitized will be shipped to your home or business location.

Can you digitize soft paper patterns manually made?

Answer: Yes, we can. Please keep in mind however that a digitizing line enhancing charge of $39.99 dollars will be made to each pattern we digitize due to not having a hard edge that prevents it from rolling up. we will need to straighten, tape or flatten any curled edges on your pattern before we can start the digitizing process.

Do I have to pay first before sending my patterns for digitizing

Answer: No, You don't. First, you will need to ship your patterns to us before we can digitize anything. Once we have received your patterns we will call you and review your patterns with you. A price quote will be given to you then.

How soon can you have my patterns digitized?

Answer: We can have all your patterns digitized as soon as next business day. However keep in mind that we always have work in process meaning we also have other clients patterns that need to be digitized, so timing will be establish according the the amount of work load we have and the day that we receive all your patterns.

What is the maximum pattern length you can digitized?

Answer: We can digitized any pattern piece that is 40" in length or width. Any pattern pieces that are longer than 40" in length can be digitized into our digitizing system however keep in mind that a cutting and merging charge of $40 dollars will be made for every pattern piece that is longer than 40"

What is the minimum digitizing charge?

– What makes us the best go-to resource for all of your garment- apparel needs?

- We’re are an all-inclusive garment business platform – a one-stop shop! There's no need to be dashing around, trying to coordinate multiple garment and apparel services.

- We’ll save you money and time. Our services are specifically tailored for those who want to bring a design to production but don't have the huge budget to pay a bunch of salaries reaching into the thousands of dollars.

- We have all the tools and technology right here at your disposal to get your fashion products developed and out into the world.

-

Other businesses similar to ours offer static, one-size-fits-all services. Our services and products are designed and developed with the specific, individual needs of our customers in mind. You can count on us to deliver personalized attention to hone in on your particular garment and apparel needs, pre-production and beyond…

You Might Also Like To Read:

The Benefits of Using a Photo Digitizing Service for Your Sewing Patterns📷

How CamScanner Revolutionize Photo Digitizing Services and Sewing Patterns📱

Looking For More Tools To Grow Your Business?