What Is Fabric Shrinkage?

Fabric shrinkage refers to any change in a fabric’s length and/or width after washing or dry cleaning. The shrinkage rate usually remains consistent whether you use a home washer, commercial laundry, or a dry-cleaning process. This matters greatly to ready-made garment suppliers because dimensional changes can affect overall fit and product quality.

Why Does Fabric Shrink?

• Material Quality: Lower-quality or unstable fibers are more prone to shrinkage.

• Manufacturing Tension: Fibers often get stretched during production; exposure to heat or moisture lets them relax, causing contraction.

In today’s competitive market, buyers expect minimal shrinkage at a low price. Consequently, manufacturers and suppliers strive to reduce shrinkage through better raw materials, controlled production, and advanced finishing techniques.

Fabric Shrinkage in the Garment Wash & Garment Dye Industries

Garment Wash: This process typically uses laundering techniques—often at elevated temperatures or with specialty washing agents—to soften the fabric or achieve a particular finish. Depending on the fiber type, this procedure can induce an additional 3–5% shrinkage if the fabric has not been preshrunk.

Garment Dye: In this method, garments are dyed after they are sewn, exposing them to chemical dyes, heat, and mechanical agitation. Natural fibers can experience up to 5–7% shrinkage if they haven’t been stabilized beforehand. This process also requires consistent monitoring of temperature and dye formulations to minimize undesired dimensional changes.

Common Natural Fiber Fabrics & Their Shrinkage

| Fiber Type | Typical Shrinkage Range |

|---|---|

| Cotton | 3–7% |

| Linen | 4–10% |

| Wool | 5–10% |

| Silk | 2–5% |

| Hemp | 3–5% |

| Bamboo (Viscose) | 4–6% |

| Ramie | 3–7% |

| Jute | 3–8% |

| Rayon (Viscose) | 5–8% |

| Lyocell (Tencel) | 2–3% |

| Kapok | 3–6% |

| Piña (Pineapple Fiber) | 2–5% |

| Banana Fiber | 3–6% |

| Coir (Coconut Fiber) | 4–8% |

| Nettle Fiber | 3–7% |

| Kenaf | 3–7% |

| Abaca | 4–9% |

| Milkweed Fiber | 2–6% |

| Lotus Fiber | 2–5% |

| Sisal | 4–10% |

Types of Shrinkage

Fabric shrinkage can be categorized based on dimensional changes:

- Expansion (rare): Fabric grows in one or more directions.

- Contraction (common): Fabric shortens in length and/or width.

Natural fibers like cotton often continue to shrink after each wash, known as progressive shrinkage. In contrast, synthetic fibers typically shrink less due to their thermoplastic structure, though they may exhibit minor changes under high heat or mechanical stress.

Shrinkage of Natural vs. Synthetic Fibers

Natural Fibers (e.g., cotton, linen, wool, rayon):

- Higher water absorption leads to greater shrinkage potential.

- Progressive shrinkage with multiple washes.

Synthetic Fibers (e.g., polyester, nylon):

- Thermoplastic structure offers better dimensional stability.

- Generally lower shrinkage (often under 2%).

Residual Shrinkage can occur if tensions from manufacturing aren’t fully removed. Wet or heated conditions release these tensions, causing further fabric contraction over time.

How to Shrink Fabric Deliberately

If a garment is too large, washing it in hot water and tumble-drying on high often induces shrinkage. However, exact control can be tricky, as different fibers respond differently. Always test a small swatch to avoid unwanted results.

Fabric Shrinkage Control

Controlling shrinkage is essential for manufacturers and garment producers. Key strategies:

- Proper Manufacturing: Minimize yarn tension; choose higher-grade fibers.

- Finishing & Preshrinking: Heat-setting (synthetics), sanforizing (cotton), or resin/softener treatments.

- Moisture Management: High humidity can increase shrinkage; control environmental factors.

- Thermoplasticity: Use steam/heat to stretch the fiber, then cool to lock in shape.

Material Shrinkage Calculation

Shrinkage depends on:

- Fiber Composition (cotton vs. polyester vs. viscose, etc.)

- Fabric Structure (loose vs. tight weave/knit)

- Processing Tension (how much yarn is stretched)

- Finishing Treatments (heat-setting, resin finishes, etc.)

- Temperature & Mechanical Action (hot water, tumble-drying, agitation)

Methods for Calculating Fabric Shrinkage

Several standardized test methods exist:

These methods typically involve multiple wash-and-dry cycles, measuring the fabric before and after each cycle. A shrinkage rate under 2–3% is usually acceptable to consumers; over 3% often causes dissatisfaction.

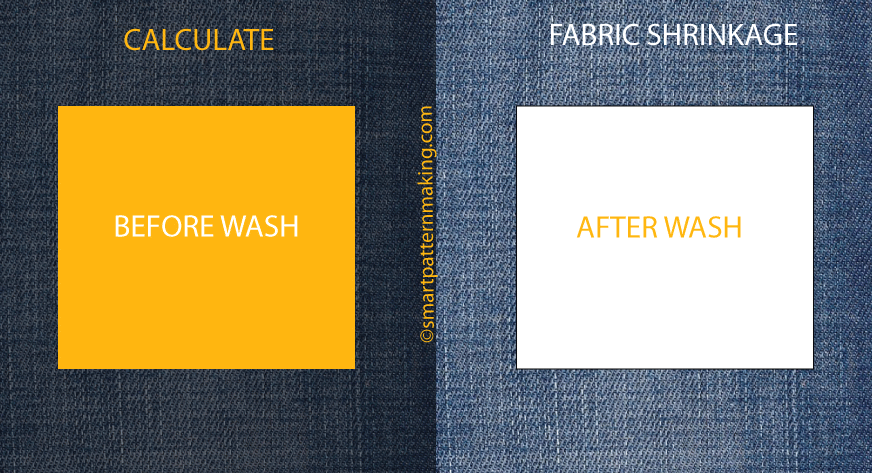

Fabric Shrinkage Formula

Follow these three steps to calculate your fabric’s shrinkage percentage:

Step 1

Cut an 18" x 18" fabric sample and mark it clearly with a fabric marker, at least 2" from the selvage.

Before Wash Measurements:

Lengthwise = 18"

Widthwise = 18"

Step 2

Wash and dry the fabric sample following your standard procedure. Then measure again:

After Wash Measurements:

Lengthwise = 17"

Widthwise = 15"

Step 3: Apply the Formula

Shrinkage % (Lengthwise) = [ (Original Length – Final Length ) ÷ Original Length ] × 100

Shrinkage % (Widthwise) = [ (Original Width – Final Width ) ÷ Original Width ] × 100

Example

• Lengthwise: [(18 – 17) ÷ 18] × 100 = 5.55% ≈ 6%

• Widthwise: [(18 – 15) ÷ 18] × 100 = 16.66% ≈ 17%

If the final measurement is larger than the original, you would get a negative result, indicating expansion (less common).

Fabric Shrinkage Rates

Shrinkage can vary widely depending on fiber type, fabric structure, and finishing. Anything under 2–3% is generally acceptable. Over 3% often leads to customer dissatisfaction, potential returns, or additional garment alterations.

Fabric Shrinkage Questions (FAQs)

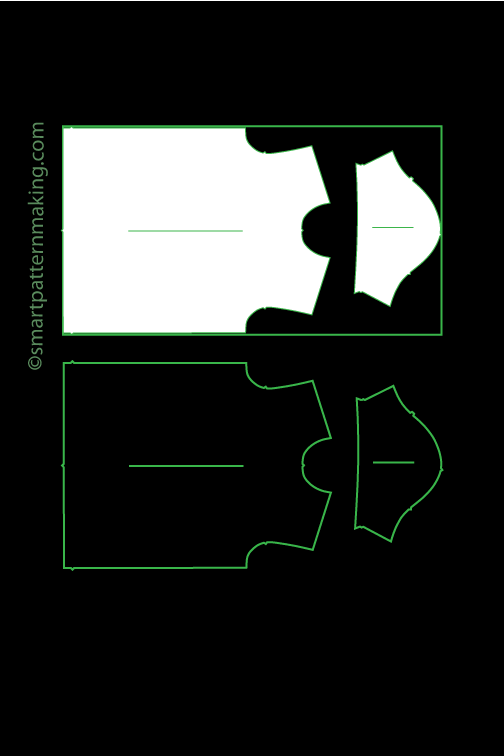

1. What Patterns Need Shrinkage Applied?

Any pattern using natural fibers—cotton, linen, silk, denim, corduroy, flannels, etc.— requires shrinkage allowances. These fibers are more susceptible to dimensional changes than synthetics.

2. What Is Selvedge (Selvage)?

It’s the tightly woven edge of the fabric that prevents unraveling. The “usable width” excludes this edge to avoid distortion or inconsistent seams.

3. Which Washing Process Shrinks Fabric?

Any wet washing or chemical process, including garment washes or dyeing, can cause shrinkage. Always test before large-scale production.

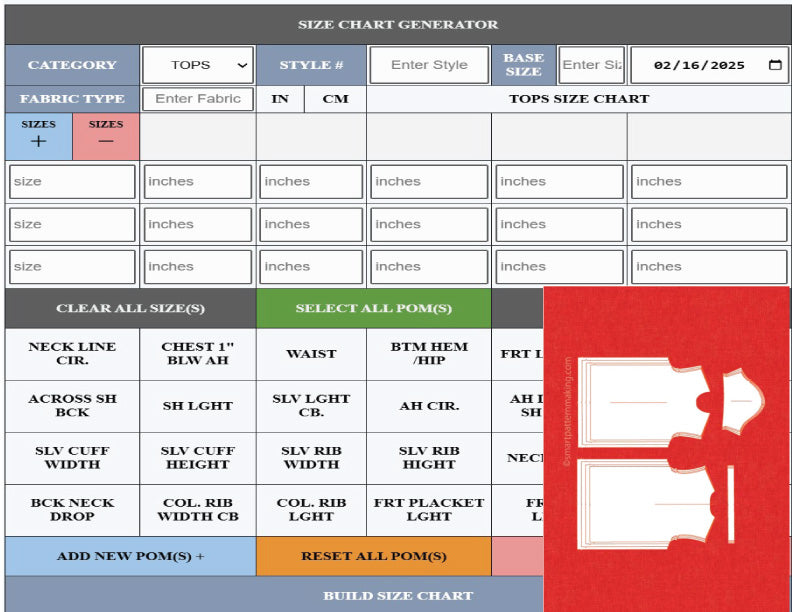

4. Which File Format Should I Upload for Shrinkage Adjustments?

You can upload Gerber ZIP files or DXF/AAMA files for digital pattern adjustments.

5. What If Shrinkage Exceeds 3%?

Many brands consider anything above 3% unacceptable. Additional preshrinking treatments or alternate finishing processes may be necessary to meet consumer expectations.

Looking to integrate correct shrinkage allowances into your patterns?

Or need assistance with your custom patterns, need to transform them into digital files, or resize them for the perfect fit, convert to DXF format, and produce your prints effortlessly! Let us help you create eco-friendly garments that look great and respect the planet—get started with us today!

Loved reading this article and found it valuable? If so, show us some love and buy us a coffee! ☕ :)

Developing tools and creating valuable content requires countless hours of work and extensive research—ensuring you have them at your disposal. Additionally, keeping this site ad-free and covering operational expenses demands significant resources.

If our work helps you, please consider supporting us. Your donation allows us to continue providing more valuable tools, fresh content, and the top-notch services you deserve.

Thank you so much for your support!

-------------------

17 comments

kevinpietersen

We read your blog and it is very beautiful and the content is also good, you have well-described about the fabric and I liked it so thank you, Washing 100% cotton with cold water can purpose shrinkage so in case you need the cotton to be shriveled intentionally use natural water in any other case regular water is the best. Does 100% cotton shrink While washing cotton withinside the machine, mild cycle and chemical-loose detergents are recommended? For heavy grimy clothes, you may use warm water. Cotton is a vegetable-primarily based totally fiber that comes from the seed pod of cotton plants. It is taken into consideration to be the workhorse of the material world, for more information visit aanyalinen.com,

Alejandro Esparza

Hello, Mohamed Iyaz pasha,🤚

QUESTION:

what is the universal standard we can accept shrinkage in garments line?

ANSWER:

It is hard to determine what is the universal fabric shrinkage standard for a particular fabric since there are several factors that contribute to the shrinkage of fabric. The fabric shrinkage percentage is determined by the length and width of fabric before and after laundering and looking at the fabric shrinkage percentage calculation.

In my experience If shrinkage % is less than 2-3%, it is acceptable by stores known to have good standards [like Target and Nordstrom’s] but there are chances of its rejection if it is more than 3%.

Md. Uzzal Miah

good method…..

Jp

Thanks for such a great info with example. would love to learn more. about fabric from your side can u plz share more details.. how cn i ?

Habibur Rahman

Valuable lesson

Md Mahmudul Hasan

carry on!!

mohamed iyaz pasha

what is the universal standard we can accept shinkage in garments line.

Abdullah

Plz let me know how can I caculate/adjust measurement discrepency according to Fabric shrinkage?

Thanks & Regards

Khalid.

Kheng Vanneth

Many thanks for your shared feature document regarded with garment.

Kokab Faraz

Greetings,

I want to start my small sewing manufacturing unit for stitching Kurtis, womens trousers and home furnishing products.

I need assistance as to how I should proceed as budget is extremely tight. I have purchased second hand kuki machine for the same.

Thanks I. Advance

MISBHA UDDIN

Thanks for share importance.

Pitt

Shrinkage Template & Ruler, suitable for all shrinkage testing standards. With high transparent plexiglass plate and the unique design on appearance, it combines the different test standards in one template.

Alejandro Esparza

Hello Stafford Heppenstall ,

Please see info. I typed below hope it gives a clear understanding of what fabric length and fabric width is.

What is fabric length ? Answer: Fabric length if referred as the total amount of yards contained in a roll of fabric. Example: when purchasing fabric from a fabric vendor they might sale you bulk fabric by the bolt or roll. Bolt (is a unit of measurement used for different types of materials including fabric that are stored in roll.)

How much is a yard of fabric? Answer: In inches a yard of fabric is = (36 inches or 3 feet). In centimeters a yard of fabric is a little over ( 90cm.)

What is fabric width? Answer: fabric width is the width of a roll of fabric from edge to edge or (salvage to salvage) The width of a bolt of fabric usually comes in this popular widths of 36, 45,58, 60 and 70 inches. Now when purchasing fabric to cut your designs or markers you must know what are your rolls of fabric usable widths as some fabrics have borders. Cuttable fabric widths are usually 1-2 inches less than the full width of your fabric depending on how your fabric salvage is finished and if any border or stripe is present at both sides of your roll of fabric.

Stafford Heppenstall

I’m sorry I have a rudimentary question and I just want a definitive answer, When calculating shrinkage is which way is width and which way is length?

Alejandro Esparza

Thank you Jakir,

Do you mean how torquing was calculated on article: HOW TO: CALCULATE PANTS SPIRALITY PERCENTAGE IN 5 SIMPLE STEPS? [ https://www.smartpatternmaking.com/blogs/pattern-making-news-articles-and-tips-smart-pattern-making-1/how-to-calculate-pants-spirality-percentage-in-5-simple-steps ] if so, what is your question?

jakir

this is important subject

Jakir

need help from your end Fabric twisting calculation.