Marker Making: How Professional Marker Making Services Maximizes Efficiency

Are you looking to streamline your marker making process? Our professional marker making services are here to help. With a focus on efficiency and accuracy, we can optimize your marker making process and save you time and resources. Learn more about our services and how they can benefit your business.

What is marker making?

Marker making is an important process in the apparel industry that involves creating stencils to guide the cutting of fabric for garment production. The marker planner, also known as the marker maker guru, is responsible for arranging the patterns in a way that minimizes fabric waste.

The efficiency of the arrangement is measured by the fabric yield, which represents the percentage of fabric cut into pieces. A high fabric yield indicates a tight marker, meaning that the patterns are arranged closely together.

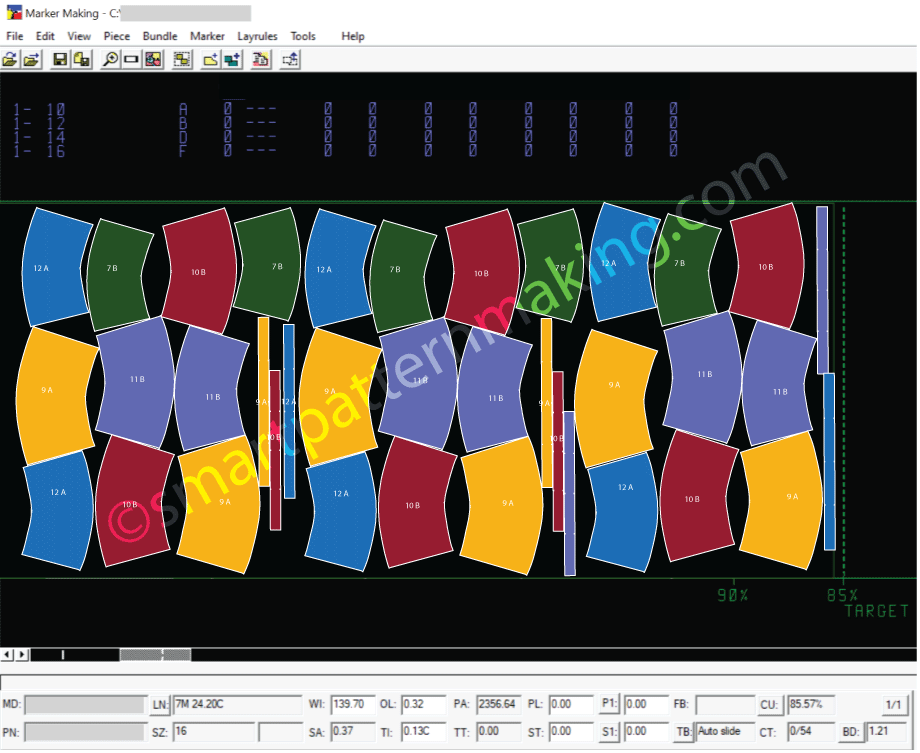

The fabric utilization refers to the percentage of fabric actually used for the garment being produced. To ensure optimal results, our marker making gurus utilize computer-aided design (CAD) systems, which help achieve high yields and tight markers, ultimately leading to bigger profits.

The benefits of professional marker making services.

here are several benefits to utilizing professional marker making services for your garment manufacturing process. Firstly, these services have access to advanced software and technology that can optimize the placement of pattern pieces on the marker, ensuring maximum efficiency and minimizing waste. This can result in significant cost savings for your business, as you will be able to make the most efficient use of your fabric.

Additionally, professional marker making services have expertise in creating markers that are accurate and precise, reducing the risk of errors during the cutting process. This can lead to improved quality and consistency in your finished products.

Finally, outsourcing marker making to professionals allows you to focus on other aspects of your business, saving you time and resources. Overall, investing in professional marker making services can help you maximize efficiency and accuracy in your garment manufacturing process, leading to improved profitability and customer satisfaction.

Our Marker Making Methods

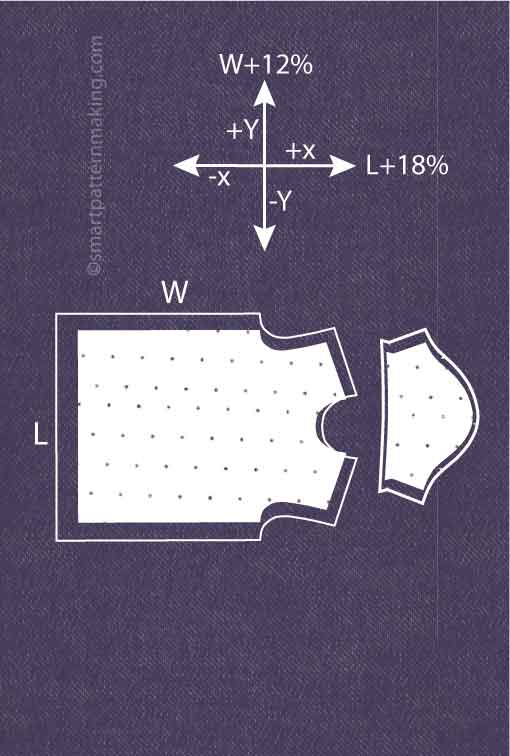

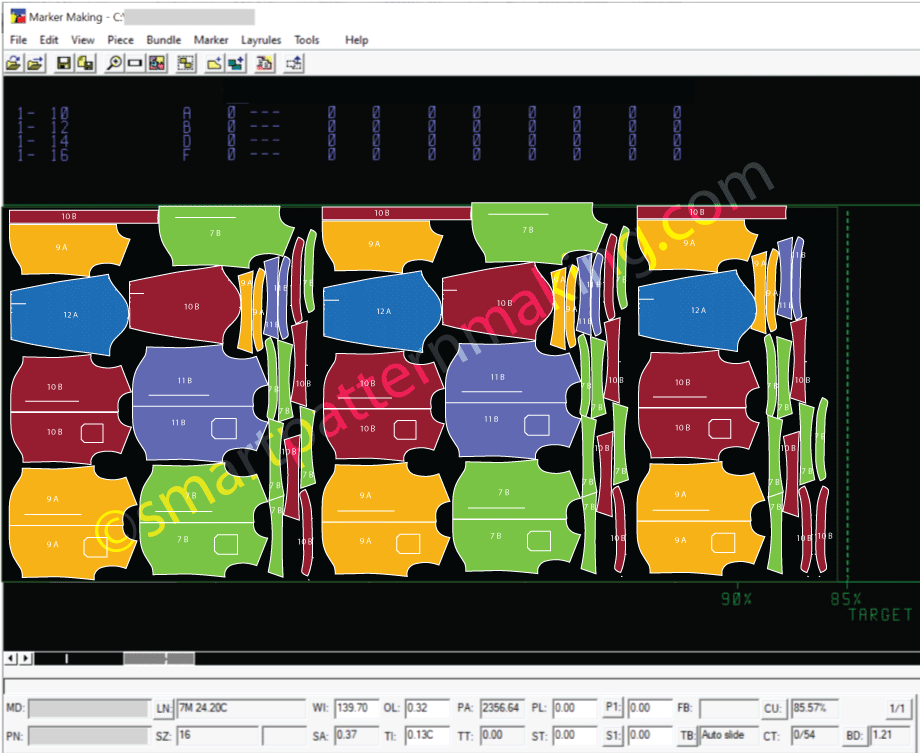

At our company, we have developed a set of marker making methods that have proven to be highly effective in optimizing fabric utilization and reducing production costs. These methods have been refined over time and are essential for successful garment production. One of our key methods is carefully considering the width of the fabric.

By strategically planning the layout of pattern pieces, we are able to make the most efficient use of the fabric's width. This may involve rotating or flipping pattern pieces to fit them closer together and minimize waste. Another important aspect is taking into account any pattern repeats or directional prints on the fabric. By aligning pattern pieces in a way that utilizes these repeats or prints, we can minimize waste and create visually appealing garments.

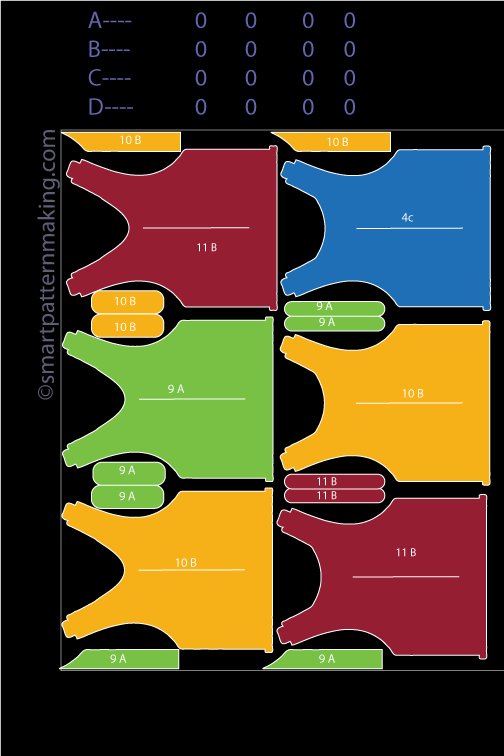

We also experiment with different nesting techniques, such as straight nesting, staggered nesting, and nested rotation. Each technique has its own advantages and can be used depending on the specific requirements of the garment production. Regularly reviewing and refining our marker making techniques is crucial to continuously improve fabric utilization.

By optimizing fabric usage, we not only reduce waste but also increase our overall production efficiency, leading to cost savings and improved profitability. By implementing these marker making methods, we have been able to achieve significant improvements in fabric utilization and production efficiency. We are confident that these techniques will be valuable for anyone in the garment production industry looking to optimize their processes and achieve better results.

[Let Our Marker Makers Make Your Life Easier – Right Here]

Use Specialized Software for Marker Making.

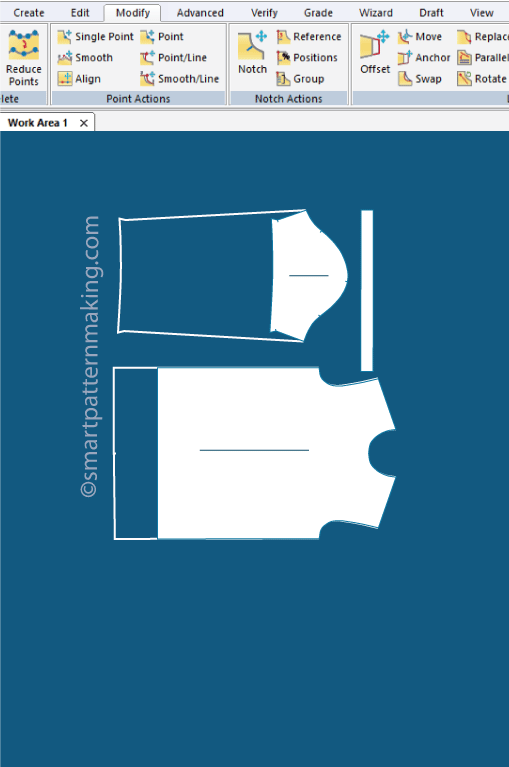

In order to effectively implement the marker making techniques mentioned above, it is highly recommended to use specialized software designed for marker making. This software allows for precise measurements, pattern placement, and nesting techniques to be easily executed.

Marker making software provides a range of features that streamline the process and ensure accurate results. It allows for the creation of digital markers, which can be easily adjusted and modified as needed. This eliminates the need for manual calculations and reduces the risk of errors.

Additionally, marker making software often includes features such as automatic pattern placement, which optimizes the layout of pattern pieces to maximize fabric utilization. It also provides options for different nesting techniques, allowing users to experiment and find the most efficient arrangement for their specific production requirements.

Using specialized software for marker making not only saves time and effort but also leads to significant cost savings. By maximizing fabric utilization and reducing waste, garment manufacturers can minimize their material expenses and improve their overall profitability.

Overall, investing in marker making software is a wise decision for any garment production company looking to optimize their processes and achieve better results. It provides the necessary tools and features to implement the essential marker making techniques and ultimately improve fabric utilization and production efficiency.

How professional marker making services can improve efficiency.

Professional marker making services can greatly improve efficiency in your garment manufacturing process. These services have access to advanced software and technology that can optimize the placement of pattern pieces on the marker, ensuring maximum efficiency and minimizing waste.

By making the most efficient use of your fabric, you can save significant costs for your business. Additionally, professional marker making services have expertise in creating markers that are accurate and precise, reducing the risk of errors during the cutting process. This leads to improved quality and consistency in your finished products.

By outsourcing marker making to professionals, you can also free up time and resources to focus on other aspects of your business. Overall, investing in professional marker making services can help you streamline your manufacturing process, improve profitability, and enhance customer satisfaction.

The importance of accuracy in marker making.

Accuracy is crucial in marker making as it directly impacts the efficiency and quality of the garment manufacturing process. A small error in the placement of pattern pieces on the marker can result in significant fabric waste and increased production costs.

By utilizing professional marker making services, you can ensure that every pattern piece is accurately placed, maximizing the use of fabric and minimizing waste. This not only saves costs but also reduces the environmental impact of your manufacturing process.

Additionally, accurate marker making reduces the risk of errors during the cutting process, resulting in consistent and high-quality finished products. Investing in accuracy in marker making is essential for optimizing your manufacturing process and delivering superior garments to your customers.

How to choose the right professional marker making service for your needs.

When choosing a professional marker making service, there are several factors to consider. First, look for a service that has experience and expertise in your specific industry. Different industries may have different requirements and specifications for marker making, so it's important to find a service that understands your unique needs.

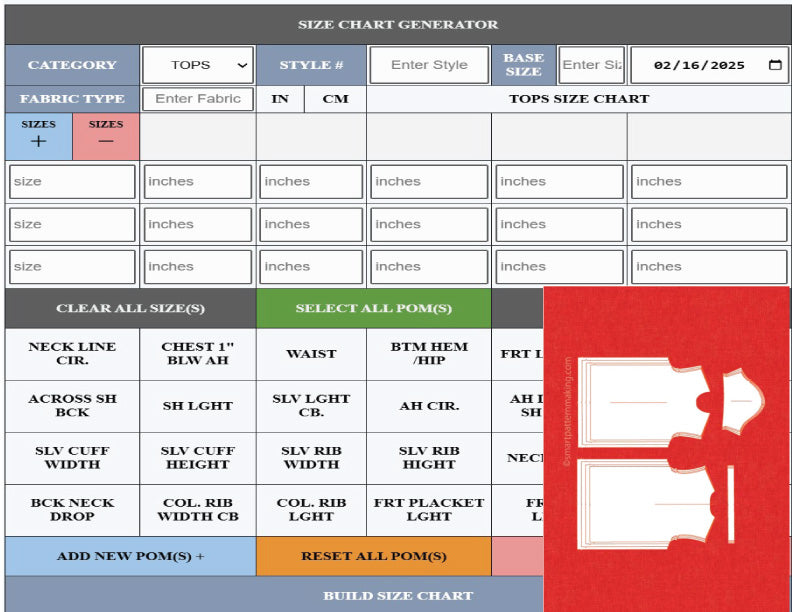

Second, consider the technology and software used by the marker making service. Look for a service that utilizes advanced software and technology to ensure accuracy and efficiency. This can include features such as automatic nesting, marker optimization, and digital pattern storage.

Third, consider the turnaround time and flexibility of the marker making service. You want a service that can deliver markers quickly and efficiently, allowing you to meet tight production deadlines. Additionally, look for a service that can accommodate changes and revisions to your markers, as design changes may occur throughout the production process.

Lastly, consider the cost of the marker making service. While it's important to find a service that fits within your budget, remember that quality and accuracy are key. Investing in a reliable and accurate marker making service may save you money in the long run by reducing fabric waste and production errors. By considering these factors and choosing the right professional marker making service for your needs, you can maximize efficiency and accuracy in your marker making process, ultimately delivering superior garments to your customers.

Top 12 Marker Making (FAQ)s

What are the most important factors to consider when marker making?

Answer: When making markers, there are several important factors to consider. Firstly, the length of the marker plays a role in efficiency. A longer marker length generally leads to higher production in the cutting room. Additionally, altering the position of patterns in the marker, known as pattern engineering, can increase marker efficiency.

The characteristics of the fabric being used also impact marker efficiency. Symmetrical fabrics tend to have higher efficiency, while asymmetric fabrics may result in lower efficiency. Similarly, fabrics with checks or stripes may also lead to lower marker efficiency.

The method used for marker making is another important factor. Computerized methods generally result in higher efficiency compared to manual methods. However, if the marker maker is highly experienced, the manual method may still yield efficient results.

Why industry gives more attention in marker making?

Answer: Marker making is given more attention in the fashion industry because it plays a vital role in optimizing fabric usage and reducing waste. Efficient marker making allows manufacturers to maximize their production output and minimize costs, leading to increased profitability. Moreover, accurate marker making ensures that patterns and designs are aligned correctly, resulting in high-quality garments. Given that the cutting room's use of cloth accounts for a significant portion of a company's turnover, any reduction in fabric usage per garment directly translates to increased profits. Marker planning is a conceptual and creative process that requires careful consideration and attention to detail.

What is the process of marker planning?

Answer: Marker planning is an essential step in the garment manufacturing process. It involves creating a layout of pattern pieces on a marker paper to optimize fabric usage and minimize waste. The process typically includes determining the marker length, selecting the most efficient marker width, and arranging pattern pieces to maximize fabric utilization. Marker planning requires careful consideration of fabric width, pattern size, and fabric grain direction to ensure accurate and efficient cutting.

Which software is used for marker making?

Answer: Some popular software used for marker making in the fashion industry include Gerber Accumark, Lectra Modaris, and Optitex. These software programs are specifically designed to create efficient marker layouts for cutting fabric and optimizing material usage.

What are the objectives of marker making?

Answer: The main objectives of marker making in the fashion industry are to optimize fabric usage, minimize waste, and ensure accurate pattern placement for efficient and cost-effective production. By creating markers, designers and manufacturers can maximize the number of garments that can be cut from a single piece of fabric, reducing material costs and environmental impact. Additionally, marker making helps to ensure that patterns are placed correctly on the fabric, avoiding any distortions or inconsistencies in the final product.

What are the factors influencing efficiency of a marker?

Answer: There are several factors that can influence the efficiency of a marker in marker making. These include the complexity of the pattern, the size and shape of the markers, the fabric type and width, the cutting method used, and the skill and experience of the marker maker. Additionally, the use of computer-aided marker making software can greatly improve efficiency by optimizing marker placement and reducing fabric waste.

What are the disadvantages of marker making?

Answer: While marker making can be a useful technique in fashion design, there are some disadvantages to consider. One disadvantage is that it can be time-consuming, as creating markers by hand can be a meticulous process. Additionally, marker making may not be as precise as other methods, such as digital pattern making, which can lead to inaccuracies in the final garment. Finally, marker making requires a certain level of skill and expertise, so it may not be suitable for beginners or those without experience in pattern making.

What is the importance of marker planning?

Answer: Marker planning is a crucial step in garment production as it helps optimize fabric usage and minimize waste. By carefully planning the layout of pattern pieces on the fabric, markers can maximize the number of garments that can be cut from a single piece of fabric, reducing costs and improving efficiency. Additionally, marker planning ensures that patterns are aligned correctly and that fabric flaws or defects are avoided. Overall, marker planning plays a significant role in streamlining the production process and improving the profitability of garment manufacturing.

What are the methods of marker making?

Answer: There are several methods of marker making in fashion design, including manual marker making, computerized marker making, and digital marker making. Manual marker making involves physically laying out pattern pieces on a marker paper. Computerized marker making uses software to create markers digitally. Digital marker making combines the use of software and digital cutting machines to create markers.

What are the objectives of marker making?

Answer: The main objectives of marker making in the fashion industry are to optimize fabric usage, minimize waste, and ensure accurate pattern placement for efficient and cost-effective production. By creating markers, designers and manufacturers can maximize the number of garments that can be cut from a single piece of fabric, reducing material costs and environmental impact. Additionally, marker making helps to ensure that patterns are aligned correctly on the fabric, resulting in high-quality finished products.

Why is CAD used in marker making?

Answer: CAD (Computer-Aided Design) is used in marker making because it offers numerous benefits. CAD allows for precise and accurate measurements, which is crucial in marker making to ensure the correct placement and sizing of patterns. It also allows for easy modifications and adjustments, saving time and reducing errors. Additionally, CAD allows for efficient nesting of patterns, optimizing fabric usage and reducing waste. Overall, CAD enhances the speed, accuracy, and efficiency of marker making processes.

How do you increase marker efficiency?

Answer: There are several ways to increase marker efficiency in the fashion industry. One tip is to optimize the marker layout by arranging pattern pieces in a way that minimizes fabric waste. Another tip is to use marker making software, which can help automate the process and improve accuracy. Additionally, using a marker plotter instead of cutting markers by hand can save time and increase efficiency.

How do I calculate the total amount of sizes that I need in my marker?

Example: If you need to create a marker for the 4 sizes you have and want to mark

each size in 4 different fabrics (SELF) (LINING) (FUSING) (CONTRAST)

just multiply your sizes in this example 4 by the number of fabrics you will be

marking each size on in this case 4 fabrics so the formula should be:

4 SIZES X 4 FABRICS= 16 SIZES IN TOTAL TO BE MARKED.

What makes us the best go-to resource for all of your garment-apparel needs?

- We’re are an all-inclusive garment business platform – a one-stop shop! There's no need to be dashing around, trying to coordinate multiple garment and apparel services.

- We’ll save you money and time. Our services are specifically tailored for those who want to bring a design to production but don't have the huge budget to pay a bunch of salaries reaching into the thousands of dollars.

- We have all the tools and technology right here at your disposal to get your fashion products developed and out into the world.

- Other businesses similar to ours offer static, one-size-fits-all services. Our services and products are designed and developed with the specific, individual needs of our customers in mind. You can count on us to deliver personalized attention to hone in on your particular garment and apparel needs, pre-production and beyond…